Utility Arm Mech

Utility Arm Mech

Utility Arm (open/close) Mechanization

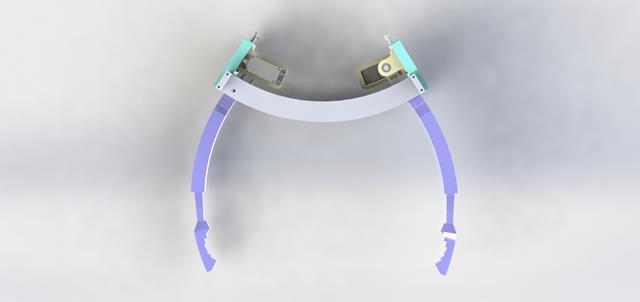

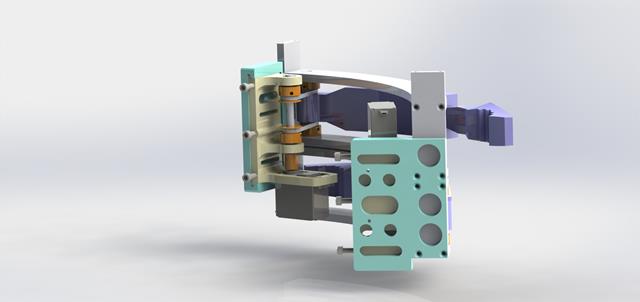

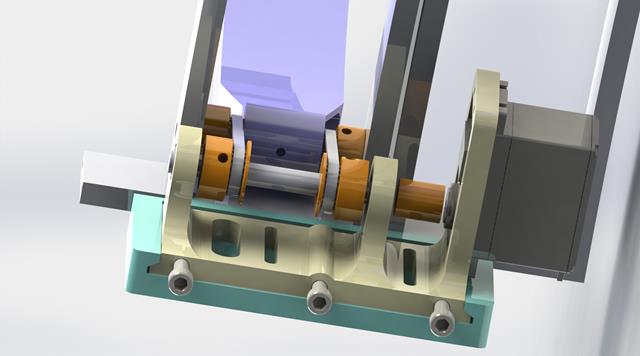

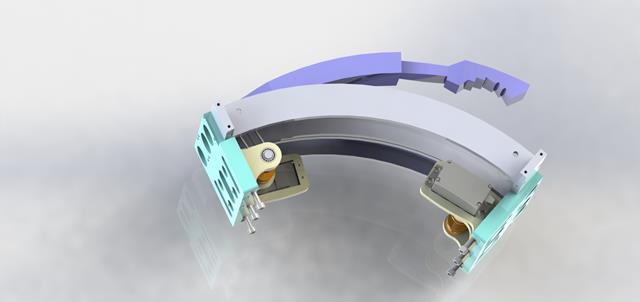

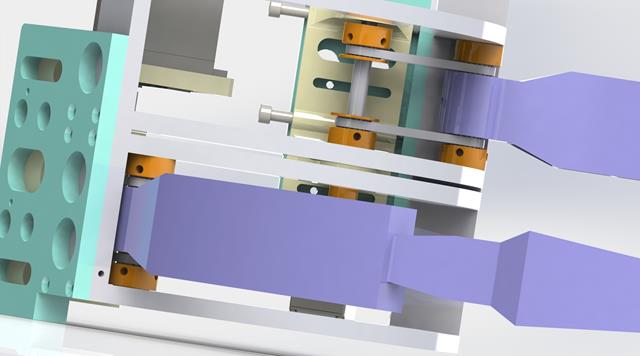

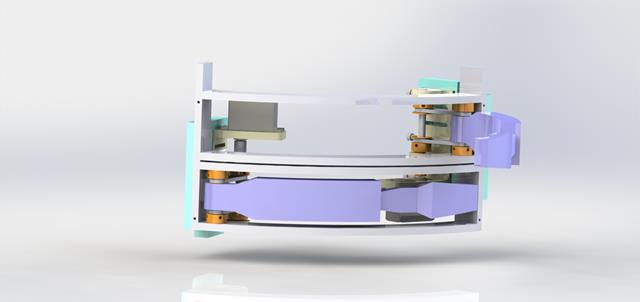

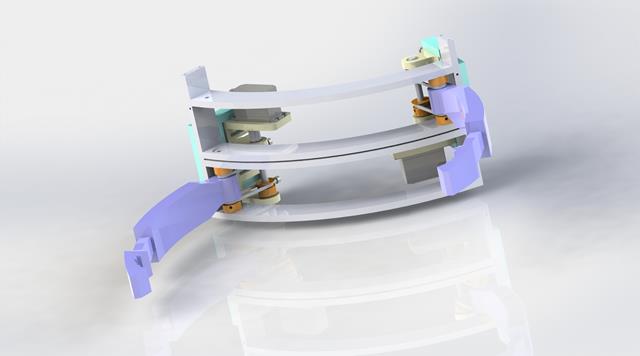

The goal is to provide a reliable and rugged system to open and close the Utility Arms while keeping the mechanics, linkages, etc., as concealed as possible. This design allows for easy tensioning of the belt & pulley system to prevent the belts from slipping and to account for variations in each droid as well as readjusting for any stretching or settling of the frame or UA carriage assembly over time. This design will have the following features: Full Travel: The system allows for full travel of the Utility Arms. The system that I am offering has a 1:1 ratio from the Servo to Utility Arms. This will allow the Arms to open a full 90 degrees with a standard servo / receiver. The servo can be driven via a microcontroller or servo stretcher to increase the overall range if desired. Concealed Hardware: The mechanization hardware is concealed nicely behind the skins and allows for a back plate to be installed behind the UA pocket. Adjustable Tension: The mechanization hardware allows the UA belts to be adjusted to the desired tension level by tightening the adjustment screws. Ball Bearings: All moving contact points have ball bearings installed to reduce friction and reduce wear on the aluminum frame / rails

.

This system will work with ANY Utility Arm — But the Utility Arms must be secured to the hinge/pivot shaft My last Utility Arm run included a #6 tapped hole for a set screw to secure the Utility Arms to the pivot shafts. Other Utility Arms will need to be drilled and taped. I actually did this with my original Utility Arm set, and it is pretty easy — I just used a hand drill and tap (no drill press required).

This design has been tested on Com8 (Budget and A) and JAG v5 Aluminum Frames I am checking to verify if this will work on the Com8-C 232 frames. I have already built and tested a prototype so I am expecting this to move quickly. I am also offering a rolled back plate to cover the UA opening. This will have all of the cut-outs for the belts and wiring for Master UA’s that have wires going into the UA housing.

The kit will include the following: 2 – Aluminum Frame Mounting Brackets 2 – Aluminum Adjustable Servo/ Bearing Mounting Blocks 4 – 1/4″ Drive Bearings 4 – 1/4″ Drive Pulleys 2 – 1/4″ Drive Shafts 4 – Timing Drive Belts 2 – 1/4″ UA Pivot Shafts 4 – 1/4″ UA Pulleys 4 – 1/4″ UA Bearings 4 – 1/4″ UA Bearing Shims 12 – #4 x 3/4” Mounting Screws 6 – #8 x 1 ¾” Tension Adjustment Bolts 2 – 1/4″ Shaft to Servo Couplers (Hitec C-spur size) ** Builders will need to install standard size (Hitec) servos of their choice. I recommend the HS-645MG or better. The price is $220 shipped in U.S. and $235 for International Shipping. The price for the back plate is $40 or $45 for anodized (black).